First Approach

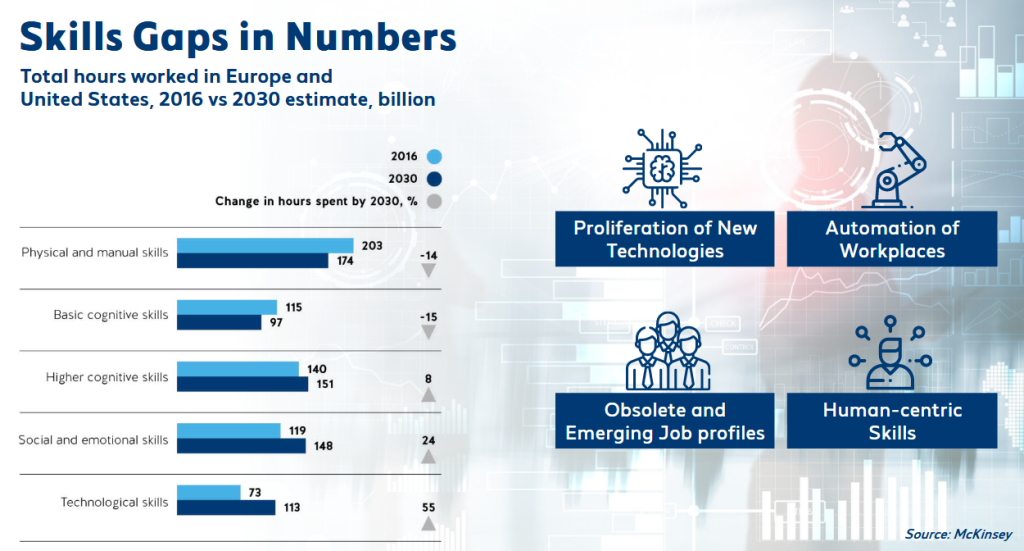

(1) As resulting from the “2019 World Manufacturing Forum Report: Skills for the Future of Manufacturing”, the skills gap phenomenon is one of the most pressing issues faced by the industry today, reinforcing the need for industries to evolve in light of new technologies brought upon by rapid digitalisation in manufacturing.

It is without doubt that manufacturing is in a time of great change and technological advancement. The so-called Fourth Industrial Revolution is moving manufacturing forward through technologies such as the Industrial Internet of Things (IIoT), Robotics, Automation, Artificial Intelligence (AI), Virtual and Augmented Reality among others. However, the disruption caused by new technology calls for new, innovative solutions that result in a change to the skills and competencies. The skills necessary to excel in this new environment are rapidly switching from manual to cognitive based skill sets to manage intelligence systems such as robotics, AI, and advanced manufacturing.

Among the top ten WMF’s skills, 7 are particularly relevant to stay competitive and face the challenges represented by 4.0 technologies:

- Digital literacy as a holistic skill to interact with, understand, enable and even develop new digital manufacturing systems, technologies, applications, tools and innovative solutions;

- Ability to use and design new AI and data analytics solutions;

- Creative problem solving in times of abundant data and technological opportunities in smart manufacturing systems

- A strong entrepreneurial mindset including proactiveness and the ability to think outside the box;

- Cybersecurity, privacy, and data information mindfulness;

- Effective communication skills with humans, IT, and AI systems through different platforms and technologies

- Open-mindedness towards constant change and transformation.

(2) The crucial and fundamental need to invest in research, to produce new knowledge and to turn the acquired knowledge into innovation is pointed out also by the “Lab-Fab-App report – Investing in the future we want”, report of the independent high-level group on maximizing the impact of EU research and innovation programmes towards 2030. In a rapidly globalising world, the success depends on the production and conversion of knowledge into innovation.

“Europe suffers from a slow growth due to its innovation deficit. Europe does not capitalise enough on the knowledge it has and produces. Europe’s challenge and ambition are straightforward: step up investment in its knowledge assets and turn the high volume and quality of its science and research results faster and deeper into innovations which generate value for economy and society. Transform knowledge into economic and societal innovation. Europe must embrace the transformative power of open science, allowing for a faster circulation of increasing amounts of knowledge, and seize the potential of open innovation to trigger faster and fairer growth”.

In the five regions involved in FUTURE 4.0, the statistics on research and innovation are discouraging despite some regions presents the high level of entrepreneurship and numerous excellent companies, especially in the manufacturing sector. It should be also considered that the model of regional development of the ADRION area is based on the birth and growth of numerous SMEs that – in addition to the “limit” of the size – are characterized especially by the adoption of B2B business models. Also, the shipbuilding and nautical sector, except some important and consolidated companies, is composed especially by small and medium-sized enterprises and the product production is the result of the supply chain.

The deep and sometimes unique knowledge of the product that distinguishes these companies, has allowed them to make incremental and continuous changes and improvements on the product and the process, but rarely have been made external investments in research and innovation as result of a continuous partnership with the centers of knowledge. There is the need to work for a better matching between the knowledge provider and enterprises and in this sense experimental action for breaking the barrier between university, center of research and enterprises, new methodologies that cut time from theory and applied knowledge.

(3) Industry-university collaboration is a powerful mechanism as it creates benefits in advancing industrial practice and generating new knowledge. As remarked by the 2019 OECD REPORT “UNIVERSITY-INDUSTRY COLLABORATION: NEW EVIDENCE AND POLICY OPTIONS”.

The OECD report provides new evidence on various formal and informal channels of knowledge exchange, including jointly field patents of higher education institutions (HEIs) and public research institutes (PRIs) with industry; the impact of local innovation of proximity to HEIs and PRIs; student and researcher start-ups. The evidence presented shows that HEIs and PRIs increasingly engage in “knowledge co-creation” with industry. Academic spin-off activities are another way for research to contribute in important ways to innovation.

With regard to policy instruments to support knowledge transfer are emerging policy approaches to knowledge transfer include support for science-industry knowledge co-creation (i.e. by means of joint labs, joint research projects, etc.); the creation of intermediary organisations that help match supply and demand for new technologies (e.g. R&D centres for science-industry collaboration, business incubators etc.), the use of new forms of open digital innovation enabled by digital platforms; and the development of new programmes to support spin-offs (i.e. the FUTURE 4.0 platform).

(4) As pointed out by the paper “In search of knowledge for innovation: a study of Italian SMEs”, one the main problem is that there is an increasing difficulty among SMEs to access and acquire new knowledge, especially technological one. The need to look for new knowledge, especially advanced and technological knowledge has been accelerated by several factors.

- The rate of technological advancement and the degree of novelty.

- The development of new transversal technologies

- More stringent. regulations on energy saving and sustainability

- The shift towards. integrated networks, the development of software-embedded logic, and the development of the Internet Of Things -IOT.

The acquisition of new external knowledge must be completed with its adaptation and integration of use within the new organisational and production context. It might be better therefore to speak about transformation rather than transfer. This transformation is driven by the learning process. The knowledge transfer process encounters many barriers. There is a tendency to consider technological transfer as limited to technological dimension in the strict sense, without considering instead the need to extend and integrate it within the wider logic of knowledge transfer. People often tend to neglect that every knowledge transfer implies a transformation.

Once this knowledge is contextualised and implemented within the new organisational situation it becomes generative competence: a knowledge has value when it generates innovation and it is put into action in a specific context. Transfer and adaptation become transformation as both technology and knowledge are transferred into new operational and managerial organizational contexts. Knowledge management is associated with the process of transforming “knowledge into value. The explored field of study shows that knowledge transfer is a wider concept and includes once again technological transfer, as well as change and learning processes. Different knowledge also implies different learning modes.